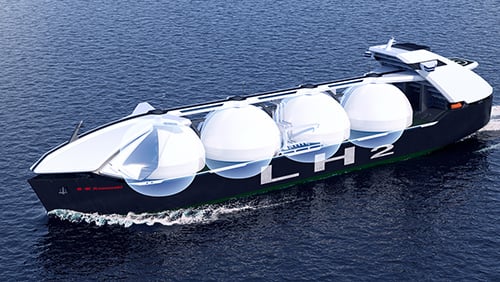

川崎重工完成液化氢运输船货物围护系统技术开发

KHI: Tech development of CCS for liquid H2 carriers completed

发布者:KnowMi 发布时间: 2023-06-13 09:06:47 点击量: 2074 来源:Offshore Energy

近日,日本川崎重工(KHI)宣布完成大型液化氢运输船货物围护系统(CCS)的技术开发。此前,川崎重工设计建造了一个测试用储罐,并进行了相关测试,以验证大型液化氢运输船货物围护系统的性能。为了实现大规模海上运输,氢气必须被冷却到-253°C进行液化,液化后的体积将缩小至气态体积的1/800,并需要长期可靠地维持在这样的低温条件下。为此,川崎重工开发了一种独特的新型货物围护系统—— CC61H,它采用球形设计,在相同的内部容积下拥有最小的外表面积,并能够最大限度地减少热量进入。该系统还具有双壳结构,可以实现高性能两级绝热。

Japan’s Kawasaki Heavy Industries (KHI) has completed the technological development for a cargo containment system (CCS) to be used in large liquefied hydrogen carriers. As explained, KHI designed and built a test tank to be used to verify the performance of a CCS for large liquefied hydrogen carriers, and conducted verification tests. In order to enable large-volume marine transportation of hydrogen, the hydrogen must be cooled to –253°C to be liquefied and reduced to 1/800 of its gaseous-state volume, and reliably maintained in these low-temperature conditions for long periods. To achieve this, Kawasaki developed a new distinctive CCS, CC61H type, for large-scale liquefied hydrogen carriers. It uses a spherical design to keep the outer surface area small relative to the inner capacity and minimize heat ingress. It also features a double-shell structure that provides high-performance, two-step thermal insulation.